Siphose imivalo yentsimbi, galela inkunkuma kwiziko leziko

1. Inkqubo yokuphosa: uShell ukungunda ngokuchanekileyo

2.I-grade ye-Steel: GX130CrSi29 (1.4777) (Kananjalo inokuba njengemfuneko yakho)

3.Unyamezelo lobukhulu be-cast: I-DIN EN ISO 8062-3 inqanaba le-DCTG8

4.Unyamezelo lwejiyometri lwe-cast: I-DIN EN ISO 8062-inqanaba le-GCTG 5

5. Isicelo: Inkunkuma kwizityalo ezitshisa amandla.

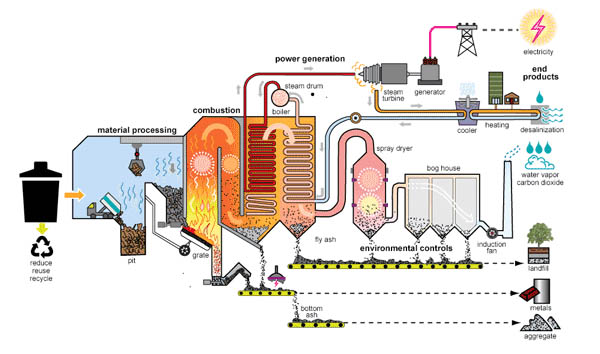

Ukulahlwa kwenkunkuma ngoku yingxaki enkulu kakhulu kwihlabathi. Inkunkuma yamandla lolona nyango lusengqiqweni. Kwiminyaka yakutshanje, amazwe amaninzi anamandla oqoqosho aqinileyo aqalisile ukuthathela ingqalelo eli nqanaba. Kutyalwe imali eninzi kulwakhiwo lwezityalo ezitshisa inkunkuma. Oku akuzange kuzise kuphela ukuphucuka okukhulu kwindalo esingqongileyo. Kwangelo xesha, isizisele iinzuzo ezinkulu zoqoqosho.

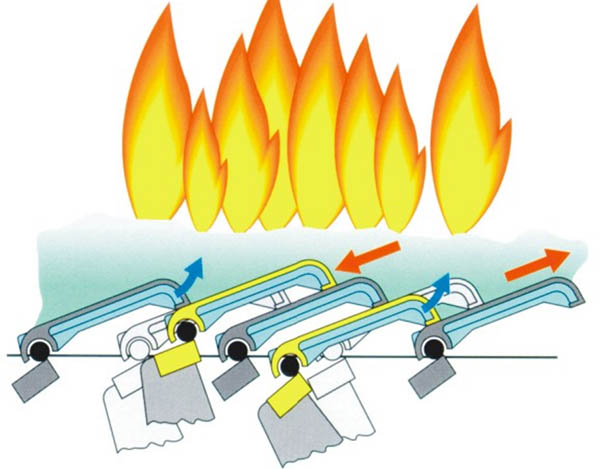

Njengoko kubonisiwe kulo mzobo, imivalo ye-grate idlala indima ebalulekileyo ekutshisweni kwenkunkuma. Kumaqondo aphezulu obushushu kunye nendawo erhabaxa kakhulu, umgangatho ophantsi wekharati uya kuchaphazela ukusebenza kokutshiswa kwenkunkuma, kwaye ubomi bayo benkonzo bufutshane kakhulu. Kuya kufuneka ubeke endaweni rhoqo.

Nangona kunjalo, ngaphezulu kweminyaka eyi-10 amava wokuphosa, sinokusombulula iingxaki kuwe.

Ibanga lensimbi esihlala siyisebenzisa. (Isenokuba kwiimfuno zakho.)

Ukwenziwa kweekhemikhali% yentsimbi ye-GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Hayi |

Mnu |

Ni |

P |

S |

Kr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

ubuninzi be-1 |

ubuninzi be-0.035 |

ubuninzi be-0.03 |

27-30 |

ubuninzi be-0.5 |

Ukwenziwa kweekhemikhali% yentsimbi GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Hayi |

Mnu |

Ni |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

ubuninzi be-0.04 |

ubuninzi be-0.03 |

25 - 28 |

ubuninzi be-0.5 |

Ukwenziwa kweekhemikhali% yensimbi ye-GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Hayi |

Mnu |

Ni |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuninzi 2 |

19 - 22 |

ubuninzi be-0.04 |

ubuninzi be-0.03 |

24 - 27 |

ubuninzi be-0.5 |

Ukwenziwa kweekhemikhali% yensimbi GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Hayi |

Mnu |

Ni |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuninzi 2 |

11 - 14 |

ubuninzi be-0.04 |

ubuninzi be-0.03 |

24 - 27 |

ubuninzi be-0.5 |

| Iipropathi zoomatshini (i-ASTM A297 iBakala HH) 1.4837 | I-UTS: Min 75 Ksi / 515 mp |

| YS: Min 35 Ksi / 240 Mpa | |

| Ukudibanisa: kwi-2 kwi: Min 10% | |

| Ubunzima: Min 200 BHN (iindawo ezi-3 kwinkangeleko) " | |

| Microstructure / Metallography | Ubukhulu becala isakhiwo saseAustenitic esinezinto ezisasaziweyo |

| IsandiTest / X-ray okanye UT | I-RT nge-ASTM E446 yeNqanaba II |

| UT nge-ASTM A609 yeNqanaba II | |

| NDT / LPI okanye MPI | MPI ngokwe-ASTM E709 / E125 INQANABA II |

| I-LPI ngokwe-ASTM E165 yeNqanaba II " | |

| Uvavanyo lokuGqibela lokuBonakalayo | Inqanaba II le-ASTM A802 |

| Iphakheji | Ityala le Iron okanye ityala le Wooden. |

Eyona Ntengiso yethu iphambili

Ii-OEMs kunye neenkampani zobunjineli

Inkunkuma kwizityalo zamandla

Iinkampani ezisebenzayo

Iiyunithi zeBiomass

Izityalo zombane ezisebenza ngombane

Iinkampani zeenkonzo zemisebenzi yolondolozo

Iindidi ezahlukeneyo zemivalo ye-OEM

Ukugqitywa kakuhle kwemivalo ye-grate

Inkqubo yokuKhula nokuLawulwa koMgangatho oQhelekileyo Kutheni usikhetha nje

Ukufumana eminye imibuzo okanye imibuzo yezobugcisa, nceda unxibelelane neQela leNkonzo ye-XTJ. Siza kubonelela ngesona sisombululo sisengqiqweni kunye nesona sicatshulwa singcono ngokwemveliso yakho.